PARAMETER

|

TYPICAL ELECTRICAL |

CHARACTERISTICS |

|||||||||

|

AT STANDARD TEST |

CONDITIONS(STC) |

|

STC:AM=1.5,irradiance1000W/m²,Component temperature25℃ |

|||||||

|

Typical Type |

Unit |

JY1-60H425PC |

JY1-60H430PC |

JY1-60H435PC |

JY1-60H440PC |

JY1-60H445PC |

JY1-60H450PC |

JY1-60H455PC |

||

|

Max-Power(Pm) |

W |

425 |

430 |

435 |

440 |

445 |

450 |

455 |

||

|

Power Tolerance |

W |

|

|

|

0~+5W |

|

|

|

||

|

Max-Operating Voltage(Vm) |

V |

33.70 |

33.85 |

34.00 |

34.15 |

34.30 |

34.45 |

34.60 |

||

|

Max-Operating Current(Im) |

A |

12.63 |

12.72 |

12.81 |

12.90 |

12.99 |

13.08 |

13.17 |

||

|

OpenCircuitVoltage(Voc) |

V |

40.00 |

40.20 |

40.40 |

40.60 |

40.80 |

41.00 |

41.20 |

||

|

Short Circuit Current(lsc) |

A |

13.42 |

13.49 |

13.56 |

13.63 |

13.70 |

13.76 |

13.82 |

||

|

Module Efficiency(nm) |

% |

19.3 |

19.6 |

19.8 |

20.0 |

20.2 |

20.5 |

20.7 |

||

|

ELECTRICALCHARACTERISTICSAT NOMINAL MODULE |

NMOT:irradiance 800W/m²,ambienttemperature20℃,wind speed¹m/s |

|||||||||

|

Typical Type |

Unit |

JY1-60H425PC |

JY1-60H430PC |

JY1-60H435PC |

JY1-60H440PC |

JY1-60H445PC |

JY1-60H450PC |

JY1-60H455PC |

||

|

Max-Power(Pm) |

W |

320 |

324 |

328 |

332 |

336 |

340 |

344 |

||

|

Max-Perating Voltage(Vm) |

V |

31.30 |

31.45 |

31.60 |

31.75 |

31.90 |

32.05 |

32.20 |

||

|

Max-Operating Current(Im) |

A |

10.24 |

10.32 |

10.40 |

10.48 |

10.55 |

10.63 |

10.70 |

||

|

Open-Circuitvoltage(Voc) |

V |

37.50 |

37.70 |

37.90 |

38.10 |

38.30 |

38.50 |

38.70 |

||

|

Short-CircuitCurrent (Isc) |

A |

10.72 |

10.78 |

10.84 |

10.90 |

10.95 |

11.00 |

11.05 |

||

ADVANTAGE

Traditional modules cannot meet the needs of modern photovoltaic integrated buildings in terms of lightweight, flexibility, functional integration, and overall performance.

·Limited Load heavyweight, bracket installation, high roof load requirements

·Safety Risk risk of self-explosion (3‰ )

·Additional costs steel structure/bracket costs, labor costs due to complex construction

·Insufficient Shock Resistance the glass module is fragile and has poor shock resistance

·Aesthetic Shortcomings single color, single shape, poor adaptability

·LIGHTEROnly 30% of the weight of traditional modules, solving the problem of insufficient load on existing roofs

·MORE FLEXIBLEIt can be better integrated into architectural design, provide more diverse appearance and integration solutions, and adapt to different curved surfaces and shapes, so that photovoltaic systems can be perfectly integrated with buildings and reduce design restrictions.

·SHINING GREEN ENERGY WORLD Through the research and technological iteration of encapsulation materials, we have solved the insufficient light transmission and weather resistance of other ordinary lightweight modules and achieved higher and more stable power generation efficiency.

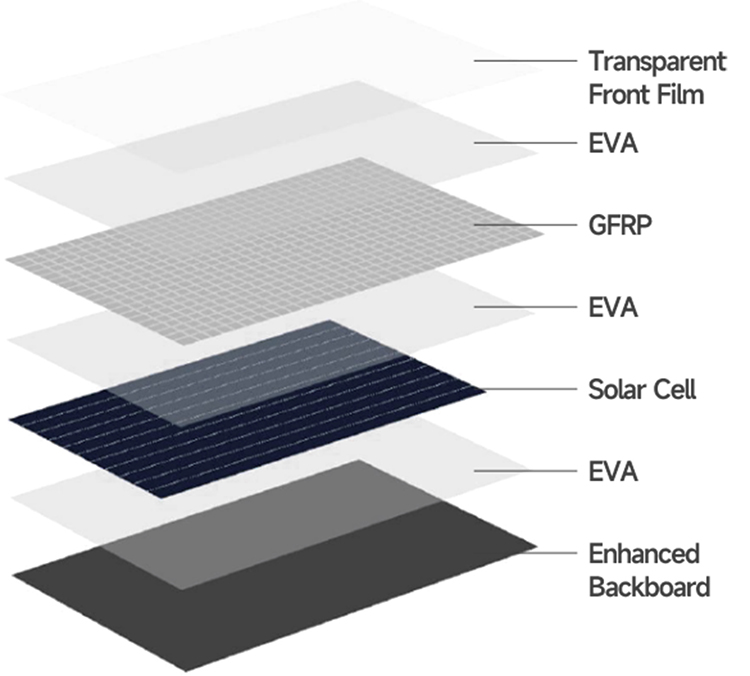

Flexible solar panels differ quite from rigid, rectangular, glass-encased standard solar panels typically found on rooftops. Rather, flexible solar panels come in all shapes and sizes and are expected to be used in a greater number of situations than standard panels Whereas portable solar panels contain solar cells mounted in a lightweight, often plastic frame and thin-film panels are made of materials like copper, selenium, and gallium, flexible and standard solar panels use solar wafers to convert sunlight to electricity. Most often, flexible panels use wafers made from silicon, though they are far thinner than those in standard panels-as thin as merely a few micrometers in width. Whereas standard panels are sandwiched between layers of glass, flexible panels are placed between layers of protective plastic.

Flexible solar panels differ quite from rigid, rectangular, glass-encased standard solar panels typically found on rooftops. Rather, flexible solar panels come in all shapes and sizes and are expected to be used in a greater number of situations than standard panels Whereas portable solar panels contain solar cells mounted in a lightweight, often plastic frame and thin-film panels are made of materials like copper, selenium, and gallium, flexible and standard solar panels use solar wafers to convert sunlight to electricity. Most often, flexible panels use wafers made from silicon, though they are far thinner than those in standard panels-as thin as merely a few micrometers in width. Whereas standard panels are sandwiched between layers of glass, flexible panels are placed between layers of protective plastic.

Off-grid or hybrid optional 6KW inverter, Max 3pcs in parallel Grade A battery cells, up to 6000+ cycles 5.5KWh battery, Max 12pcs in parallel Easy to install, combined freely BMS & battery capacity auto-sense WiFi/GPRS remote monitoring (optional)

The solar hybrid AC/DC air conditioner can work without battery, it works with unstable solar panel DC power at day time. At night or rainy days it automatically get grid AC power. It's mainly used for school classroom, hospital, restaurant, shops, office… With APP monitor and control function through WIFI

Off-grid solar energy systems is mainly composed of photovoltaic modules, controllers, inverters, batteries and other accessories The working principle of the solar panel system is that the photovoltaic module converts light energy into direct current, and the direct current is converted into alternating current under the action of the inverter, and finally realizes the power consumption function. It can be for Home applications, Commercial applications and Industrial applications. Inverter power: 5kW AC output voltage: AC110V/120V Battery voltage: DC24V or DC48V Battery type: Gel battery or LiFePO4 battery Solar panel type: Mono or poly Compatible with grid and generator Monitor: WIFI or GPRS

Flexible solar panels differ quite from rigid, rectangular, glass-encased standard solar panels typically found on rooftops. Rather, flexible solar panels come in all shapes and sizes and are expected to be used in a greater number of situations than standard panels Whereas portable solar panels contain solar cells mounted in a lightweight, often plastic frame and thin-film panels are made of materials like copper, selenium, and gallium, flexible and standard solar panels use solar wafers to convert sunlight to electricity. Most often, flexible panels use wafers made from silicon, though they are far thinner than those in standard panels-as thin as merely a few micrometers in width. Whereas standard panels are sandwiched between layers of glass, flexible panels are placed between layers of protective plastic.

The 80kW off-grid solar system is suitable for commercial power stations. It has an intelligent power generation platform and energy storage system. It can be compatible with generator to save fuel bill. Inverter power: 80kW power frequency inverter AC output voltage: AC120V/240V split phase or three phase 208V/380V Battery voltage: DC360V Battery type: Gel battery or LiFePO4 battery Solar panel type: Mono or poly

1. Intelligent management system and multiple working modes, meeting different customer needs 2. Allowing you to set the priority of grid connection, battery type and other inverter information on the LCD screen. 3. Dual MPPT, high current input, compatible with large solar cell module of 210mm, flexible configuration, 4. All-in-one design, providing backup power and peak-shaving function. 5. With a battery safety management system, supporting the remote upgrade of BMS system.

IPv6 network supported

IPv6 network supported